What is Mechanical BIM?

Mechanical BIM (Building Information Modeling) is a specialized application of BIM technology that focuses on designing, modeling, coordinating, and managing mechanical systems in a building.

These systems typically include:

HVAC (Heating, Ventilation, and Air Conditioning)

Plumbing

Fire protection

Mechanical equipment like pumps, chillers, boilers, fans, etc.

Components of Mechanical BIM

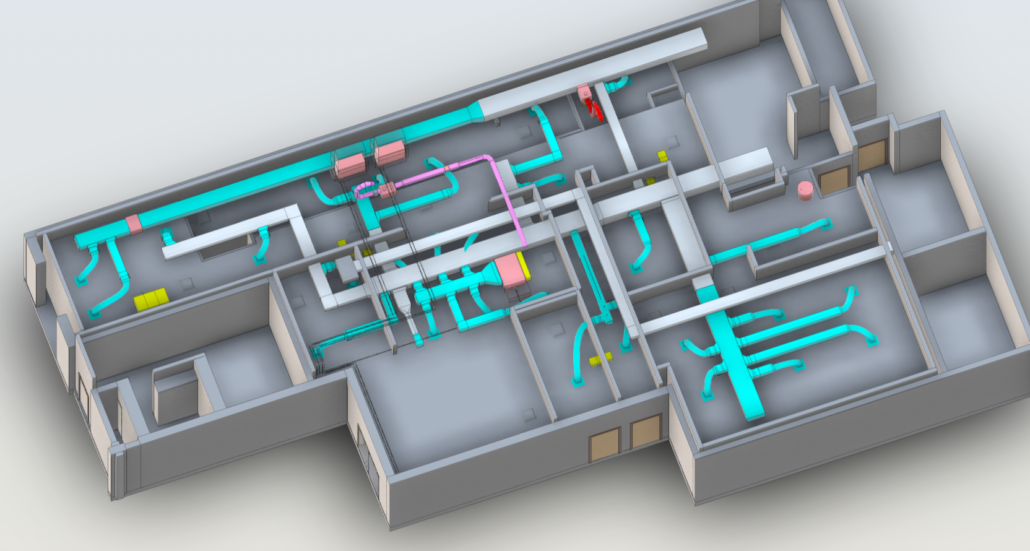

a. HVAC Systems

Involves modeling ducts, air terminals, chillers, and air handling units. These systems are essential for maintaining indoor air quality and thermal comfort.

Example:

BIM can simulate airflow patterns in a shopping mall to identify areas with poor ventilation and adjust duct layouts before construction.

b. Plumbing Systems

Covers domestic water systems, drainage, and stormwater management. BIM ensures correct pipe sizing, slope, and collision-free routing.

Example:

In a high-rise building, BIM helps coordinate vertical stacks and avoid clashes with structural beams and electrical conduits.

c. Fire Protection Systems

Includes sprinklers, fire pumps, and alarm integration. BIM helps ensure regulatory compliance and adequate coverage.

Example:

A warehouse design can use BIM to visualize and validate sprinkler head locations for complete fire coverage.

d. Mechanical Equipment and Layout

Placement of chillers, boilers, cooling towers, etc., in mechanical rooms and rooftops, considering accessibility for maintenance.

Example:

BIM can flag issues like insufficient clearance around an air handler, which would otherwise be discovered only during installation.

Key Benefits of Mechanical BIM

a. Improved Design Coordination

Mechanical BIM helps different disciplines (architectural, structural, electrical, and mechanical) to work together in a shared 3D model. It drastically reduces errors and on-site rework.

Example:

The mechanical ductwork in an airport terminal is designed to weave around complex steel structures using clash detection tools.

b. Clash Detection and Resolution

BIM identifies clashes between mechanical systems and other building components before construction.

Example:

Detecting a conflict where a hot water pipe intersects a steel beam and resolving it by rerouting the pipe virtually.

c. Enhanced Accuracy in Construction Documentation

BIM generates precise drawings and specifications automatically from the model.

Mechanical BIM automatically generates up-to-date drawings like plans, sections, elevations, schedules, and isometric views. For example, When a duct size is updated in the model due to airflow changes, all related fabrication drawings and schedules update automatically.

d. Cost Estimation and Quantity Takeoff

In BIM, all mechanical components (pipes, ducts, valves, chillers, etc.) are modeled with real dimensions and materials. It helps improve coordination, reduce material waste, prevent rework, and enable smart decisions.

e. Lifecycle Management and Maintenance Planning

Once construction is complete, the BIM model becomes a valuable asset for building maintenance. BIM models handed over to facility managers with embedded data like service history, part numbers, and manuals.

Mechanical BIM in Different Project Phases

Conceptual and Design Development

In the conceptual and design development phase, Mechanical BIM is used to plan and visualize mechanical systems such as HVAC, plumbing, and fire protection.

Construction Documentation and Fabrication

Mechanical BIM streamlines the production of detailed shop drawings, specifications, and quantity takeoffs. It allows contractors to extract the model’s accurate material lists and fabrication data.

Installation and Commissioning

Mechanical BIM ensures the mechanical systems are installed exactly as intended. BIM provides detailed layouts and spatial references that contractors can access using mobile devices or site scanners. This minimizes installation errors and speeds up commissioning.

Facility Management and Operations

Facility managers use the as-built model, enriched with embedded equipment data, to monitor system performance, track maintenance schedules, and plan upgrades.

Challenges in Implementing Mechanical BIM

Need for Skilled Personnel

Requires trained professionals who understand both mechanical systems and BIM tools. One of the most prominent issues is the shortage of skilled professionals who are proficient in both mechanical engineering principles and BIM software tools like Revit or Navisworks.

Integration with Other Disciplines

Mechanical systems often need to be tightly coordinated with architectural designs, structural layouts, and electrical routes. In large-scale or complex projects, poor communication or lack of a centralized BIM management strategy can result in misalignment between disciplines, leading to clashes or inefficiencies that negate the benefits of BIM.

Data Management and Interoperability

Various stakeholders may use different software platforms, such as AutoCAD MEP, Revit, MagiCAD, or Fabrication CADmep, and transferring models between these platforms can result in data loss or formatting issues. Data interoperability is a recurring issue in Mechanical BIM implementation.