What is electrical BIM ?

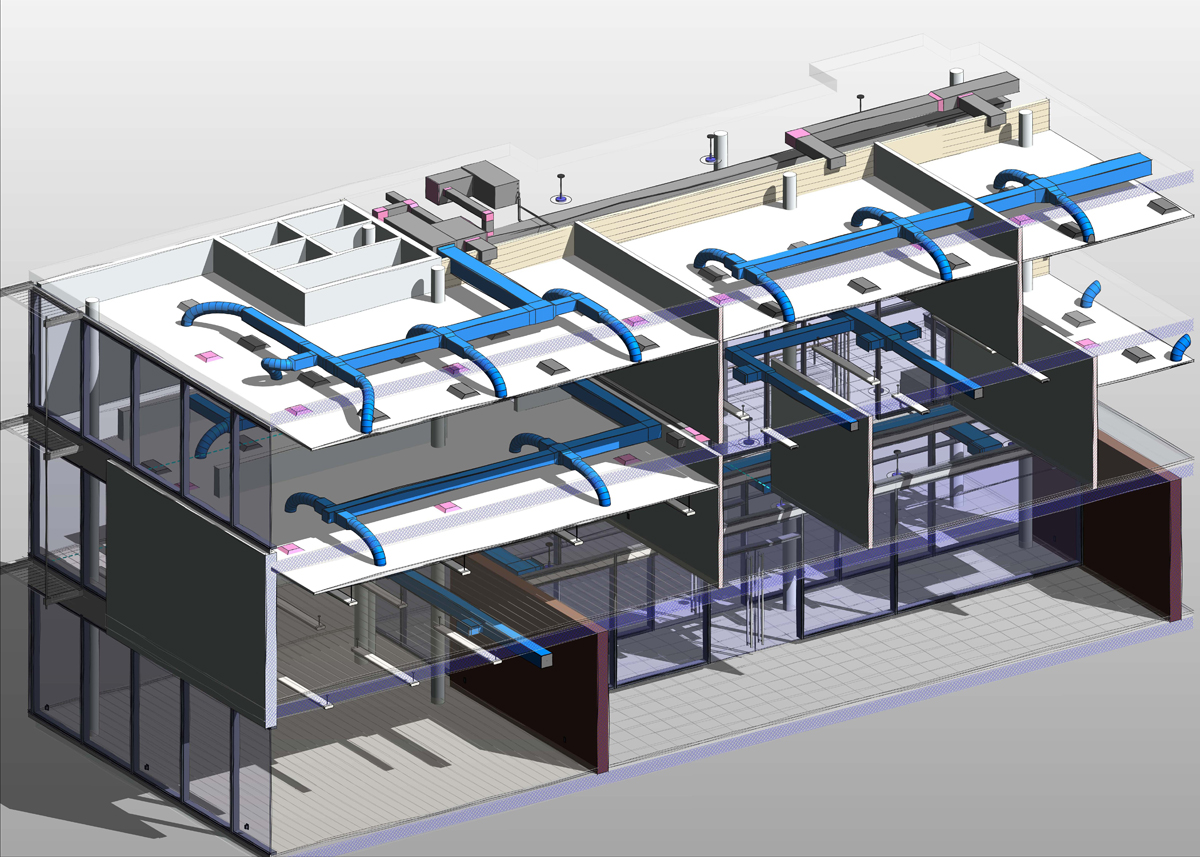

Electrical BIM (Building Information Modeling) represents the digital transformation of how electrical systems are planned, designed, coordinated, and maintained throughout a building’s lifecycle. It offers more than just 3D models—it’s about data-rich representations that empower engineers, contractors, and facility managers to make informed decisions, reduce errors, and streamline operations.

Role of Electrical BIM in Construction

Electrical BIM helps visualize and simulate electrical infrastructure such as

- Lighting Systems

- Power Distribution

- Fire Alarm Systems

- Data and Communication Lines

- Emergency Systems (UPS, Generators)

Through BIM, these systems are integrated within a digital model that aligns with architectural, structural, mechanical, and plumbing designs, ensuring holistic coordination and conflict resolution before construction begins.

Key Components in Electrical BIM Modeling

Power Distribution Layouts

At the heart of any electrical BIM model is the power distribution layout. This involves modeling main distribution boards (MDBs), sub-distribution boards (SDBs), and final circuit panels. These components are not only placed in the model but also interconnected through risers, cable trays, or busbars, all of which reflect accurate load capacities and circuit relationships.

Lighting Analysis

Lighting systems are modeled with precision, focusing on both physical layout and performance simulation. Light fixtures, switches, motion sensors, and dimmers are placed in accordance with space function and lighting standards.

Conduit Routing and Clearance Analysis

In BIM, conduit paths, cable trays, and trunking are not drawn in isolation—they are spatially coordinated within the model to avoid clashes with HVAC ducts, structural beams, or plumbing lines. The 3D visualization also considers bend radius constraints, conduit fill capacities, and thermal separation requirements, ensuring practical constructability and safety compliance.

Load calculations and cable sizing workflows

By analyzing the devices connected to a panel or circuit, BIM tools can dynamically calculate electrical loads, apply diversity factors, and determine the proper cable size and protective device ratings. These calculations are updated in real time—so when a piece of equipment is added or modified, the load analysis and cable requirements reflect those changes instantly.

Single-line diagrams

BIM model generates automated schematic and single-line diagrams (SLDs) based on the 3D model inputs. These diagrams are always synchronized with the model, eliminating manual drafting errors and ensuring consistency between visual layouts and electrical documentation. These outputs are essential guides for on-site electricians and engineers during construction and commissioning.

Circuiting and panel scheduling

Within the BIM environment, all devices are linked to panels and circuits, and the data is automatically fed into panel schedules. These schedules include details like breaker size, circuit ID, connected load, phasing, and more. Importantly, any model changes are mirrored in these schedules, ensuring that documentation stays up-to-date and accurate.

- 3D Modeling of Electrical Fixtures: Switchboards, conduits, panels, transformers, and sockets.

- Load Calculations & Cable Sizing: Based on space use, demand factors, and local codes.

- Panel Schedules and Circuit Diagrams: Automatically generated and updated as the model evolves.

- Conduit Routing and Clearance Analysis: Ensures there’s no clash with structural elements or HVAC ducts.

- Lighting Analysis: Integrated tools for lux level analysis and daylight simulation.

Benefits of Electrical BIM

- Improved Design Accuracy: Electrical BIM empowers stakeholders at every stage of a project. Designers benefit from accurate modeling and simulation, contractors benefit from coordinated construction and reduced risk, and owners benefit from improved asset performance and lifecycle management.

- Cost Estimation & Quantity Take-off: Electrical BIM enhances cost estimation and material management. Since every component—from a light switch to a power panel—is modeled with exact quantities and specifications, contractors can extract detailed Bills of Materials (BOMs) and perform accurate quantity takeoffs.

- Faster Permitting and Approval: Electrical BIM models have parameters aligned to local and international standards, such as the NEC (National Electrical Code), IEC regulations, or regional building codes. It allows automatic validation of designs for load capacities, fault protection, emergency circuit requirements, and more.

- Facility Management: Electrical BIM creates long-term value by supporting facility management and operations. Once construction is complete, the BIM model is a digital twin of the electrical systems, providing detailed information about equipment specifications, maintenance schedules, and performance logs. Facility managers can use this data to plan preventive maintenance, troubleshoot faults quickly, and assess upgrade needs without extensive manual audits.

Challenges in Electrical BIM Implementation

- Steep Learning Curve: Electrical design has traditionally been done in 2D environments using software like AutoCAD, and shifting to 3D modeling in platforms like Revit MEP requires both technical upskilling and a change in design thinking. Engineers must understand how to place elements in 3D and manage embedded data, simulate electrical behavior, and ensure accurate interconnectivity between systems.

- Interdisciplinary Dependencies: Electrical BIM models do not exist in isolation—they rely on coordinated inputs from architects, structural engineers, and mechanical teams. If the architectural layout or HVAC design is delayed or frequently changes, it directly affects the routing of conduits, placement of distribution boards, and alignment of lighting layouts.

- Data Management: Data overload and model performance can become problematic, especially in large-scale or complex projects. Electrical BIM involves modeling thousands of components with its own set of parameters, tags, and metadata.

- Standards Variation: Different projects, clients, and regions often follow varying standards for BIM execution plans (BEPs), naming conventions, and data structures. Electrical codes may differ based on geography (e.g., NEC vs. IEC), and unless BIM templates and families are tailored accordingly, the model can fail to meet local compliance requirements. Inconsistent modeling standards also make collaboration between firms difficult, leading to inefficiencies and errors in shared models.